To sustain the pressure in the drum you must control the rate of coal that’s burned in the boiler. The correct levels are 150 bar for drum pressure and 50% for drum level. The power rate is controlled by opening/closing the steam valve, the delivers the steam to the steam turbines hence rotating the shaft that’s connect to the power generator.Īs you open/close the steam valve pressure and water level decreases/increases.

To ensure that plant is operating between acceptable levels (green marks in the dials) at each power rate.

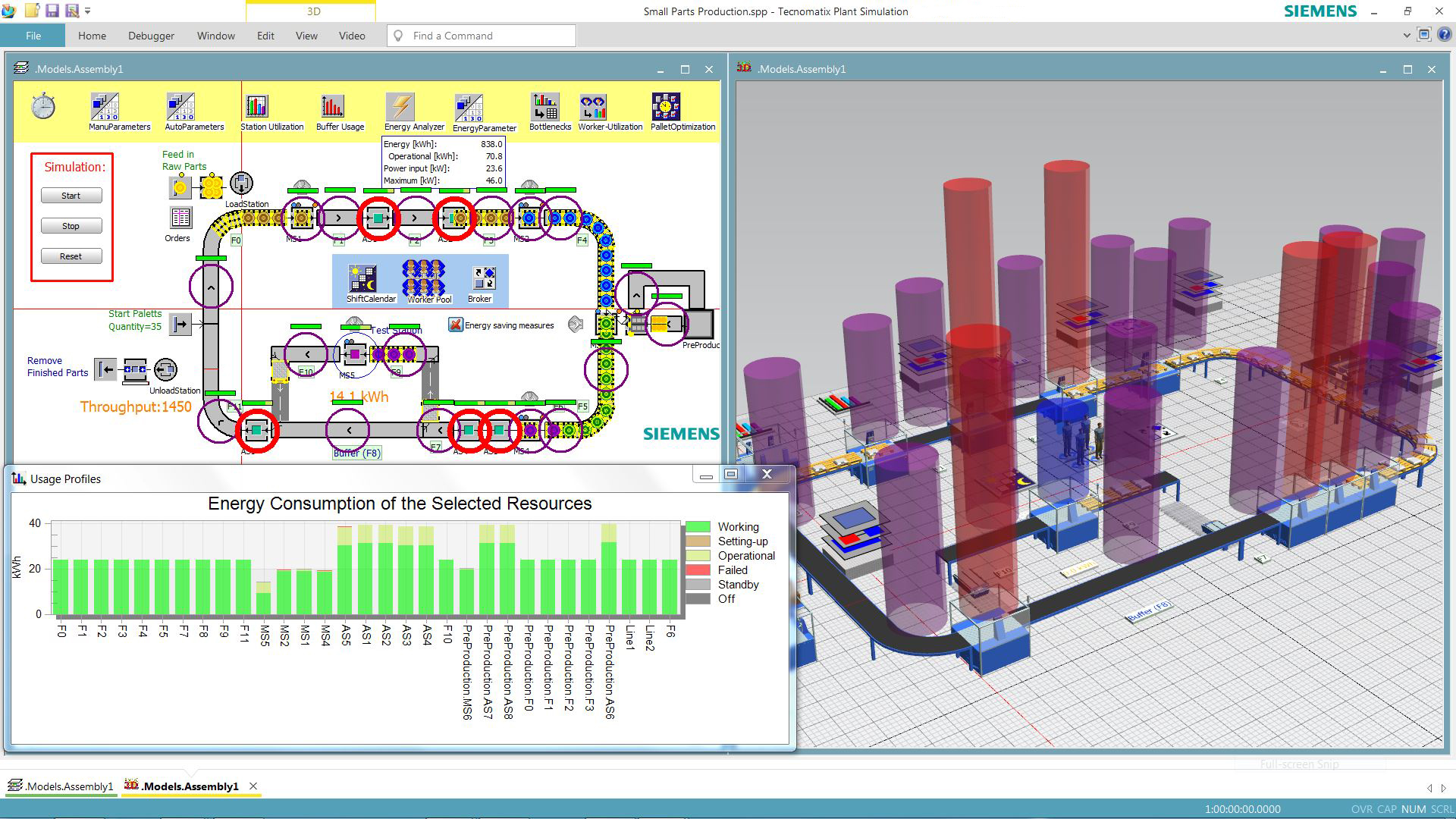

#Plant simulation community simulator#

It's intended to be a power station simulator but at simpler level. The “rotation” of the shaft “produces” electricity. The “process” of generating power in a thermal power station is “very simple” – heat water to steam, then drive it through a steam turbine which shaft is connect to a power generator. So I decided to make a power plant simulator (kind off.) I like power plants … especially thermal power plants.

0 kommentar(er)

0 kommentar(er)